Why We Exist

Connected Fabrication Solutions was created to help fabrication businesses see their operations clearly before trying to change them.

Too many shops struggle not because their people lack effort or skill, but because priorities conflict, information is fragmented, and responsibility does not match authority. When reality is unclear, even good teams are forced into constant firefighting.

We believe meaningful improvement starts with visibility and understanding, not quick fixes.

Our Perspective

We approach fabrication consulting as an independent observer, not a replacement for leadership or management.

Our role is to surface constraints, tradeoffs, and system behaviors that are often invisible from inside the operation. We reflect what we see back to leadership in a practical, grounded way so decisions can be made deliberately rather than reactively.

We do not impose solutions. We help organizations see clearly enough to choose their own path forward

Real-World Experience

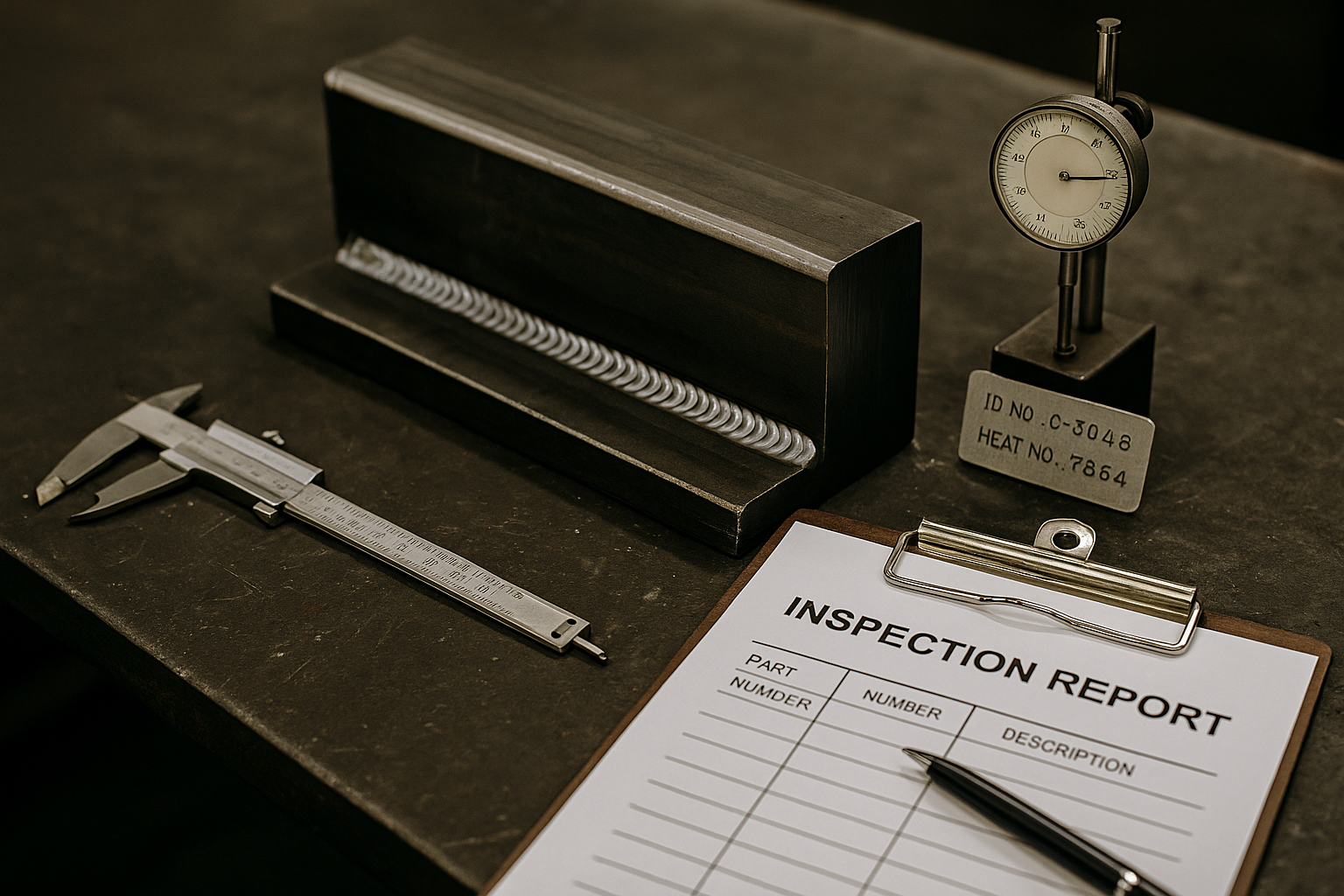

Our work is informed by hands-on experience inside fabrication shops, quality systems, and complex production environments.

We understand the realities of shop-floor execution, quality and compliance requirements, and the tension between delivery commitments and available capacity. That experience shapes how we observe, communicate, and recommend change.

This background allows us to focus on what actually works in real fabrication environments, not what looks good on paper.

How We Think About Change

We believe sustainable change happens when:

reality is visible

decisions are deliberate

accountability matches authority

Our work is designed to reduce noise, clarify tradeoffs, and support better decision-making over time. Change follows clarity, not the other way around.

If your organization values clarity over blame, we welcome a conversation.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!